Event

Fermentation

Village Life

Food

Plants

Games

Thursday, 22 May 2025

Now Open: cofunia – A Sensory Retreat along the Yamanobe Ancient Trail, Nara

In 2021, It All Began with a simple post on SNS, “We’ve inherited a kofun. Anyone want to use it?”

—and to our surprise, it struck a chord. Many people asked, “You can inherit a kofun?”

In Japan, there are over 160,000 kofun (ancient burial mounds), many of which quietly exist in everyday life—as farmland, parks, or private land.

At the foot of the 114-meter-long Nishiyamazuka Kofun stood a cluster of seven traditional houses, over 100 years old. Long abandoned, they had fallen into ruin.

From Abandoned to Alive Again as accomodation

The houses were nearly beyond repair—leaking roofs, collapsed beams, ghostly silence. It would have been easier to tear them down.

But we felt something here: a presence of time we didn’t want to erase.

While most architects said it was faster to demolish, "Team Clapton"— a group of architects, believed in restoration. Together with volunteers from across Japan and abroad, we began the renovation.

In 2025, cofunia Opened

Three years later, cofunia officially opened in March 2025.

It’s the first accommodation in Japan where guests can stay at the foot of a kofun.

The concept: Five Senses × Five Elements

Each of the four guest rooms is inspired by an element of ancient East Asian philosophy—Wood, Fire, Earth, Metal, Water—and offers a unique sensory experience.

Meals are served in the communal Fire Building, celebrating local ingredients, fermentation, and herbal traditions.

A Place to Rest—and Reconnect

A portion of each stay helps support the preservation of Nishiyamazuka Kofun.

The mound, once an orchard, is gradually being restored and opened to the community—today, you can even enjoy tea atop it.

Kofun are final resting places—but they also quietly offer wisdom for how we live today.

At cofunia, we hope to continue nurturing a way of life where people and kofun can coexist.

A Garden in Spring

This spring, we harvested tea leaves from the garden during Hachijūhachi-ya, the 88th night of the traditional calendar. With the scent of herbs in the air, we pan-fried the fresh leaves and sipped our own handmade tea.

The garden is waking up—plum blossoms swelling, grasses sprouting—and with it, the rhythm of cofunia as a place of rest has begun.

It’s a quiet, gentle space where the body and spirit can soften.

We look forward to welcoming you.

Chisato Maeda @ cofunia

-----

cofunia

Email: reservation@cofunia.co.jp

Tel: 0743-20-6393

Address: KAYOCHO, TENRI-SHI, NARA, 632-0042, JAPAN

HP:https://en.cofunia.co.jp/

IG:https://www.instagram.com/cofunia.nara/

Monday, 27 January 2025

Discovering the Plant Wisdom and Fermentation Culture of Taiwan’s Indigenous Amis People

Taiwan’s indigenous communities possess a rich knowledge of plants and fermentation that reflects their harmonious coexistence with nature.

On a recent trip, we visited an Amis village, guided by professors and students from Pingtung University of Science, along with a team from Japan’s leading Koji-maker. This journey opened a window into the incredible food culture and plant wisdom of the Amis people, blending ancient traditions with insights from modern science.

A Table Rich with Fermentation

The Amis people’s food culture is a paradise of fermentation. Their dining tables are filled with unique creations like matured pork sushi, pickled fish roe, salted pork offal, and fermented fish eggs. These dishes seamlessly combine the bounty of the sea and the mountains, offering a distinctive culinary experience.

Interestingly, the fermentation of meat and fish was also recorded in Japan’s Engishiki from the Heian period. It described “meat miso” (nikusho) and “fish miso” (gyosho), which have largely disappeared from Japanese cuisine. However, these traditions are still alive in the Amis villages, where wild boar meat is freshly prepared into a fermented paste or cured with salt, creating flavors rooted in sustainability and heritage.

Wild Plants and fermentation

One of the most striking aspects of the Amis culture is their deep understanding of wild plants. According to Wu Xueyue, principal of the Indigenous Vegetable School in Hualien and author of Vegetarian Doctrine, the Amis recognize over 200 types of wild plants, with more than 100 making regular appearances on their tables.

During my visit to the Indigenous Vegetable School, just a short walk from Hualien Station, I was amazed by their thriving garden of wild plants. Visitors can enjoy a guided tour of the garden. This hands-on experience highlighted the sheer diversity of wild plants used in their daily cooking, from herbs with medicinal properties to flavorful greens.

Nourishing Alcohol: Herb-Infused Rice Malt Wine

The Amis also good at creating unique fermented beverages. Their rice malt wine is crafted using 12 different types of plants, each selected for its medicinal benefits, aroma, and preservative properties. Unlike herbal tinctures, where plants are soaked in alcohol, the Amis incorporate these plants directly into the fermentation process, making the plants an integral part of the alcohol itself.

The result is a nourishing, health-boosting wine that combines the benefits of natural fermentation with plant-based medicine. This innovative approach to fermentation reflects the Amis people’s ability to blend practical knowledge with cultural traditions.

Wild Cooking Techniques

The Amis people’s cooking methods are as fascinating as their ingredients. One standout technique involves heating stones until they’re red-hot and then placing them into a bowl of soup made with wild herbs, served in a betel nut leaf bowl. The sizzle of the hot stones creates a fantastic display, releasing aromatic flavors into the soup and adding a wild, earthy touch to the meal.

Their resourcefulness extends to fishing methods as well, using plant-based toxins to stun fish and intricately woven bamboo nets to catch them—a perfect example of sustainable living that respects natural ecosystems.

Bringing Indigenous Knowledge to Japan

Inspired by these experiences, we’re organizing a fermentation camp in Nagano at the end of August. The goal is to recreate Amis-style fermented foods using Japanese wild plants. By understanding why the Amis chose specific plants for fermentation, we hope to adapt these techniques to local ingredients.

In addition, our ethnobotanical food workshops this month will feature recipes inspired by the Amis village. The menu includes:

• Taroko Tribe’s Wild Millet Porridge

• Amis-Style Stir-Fried Matured Pork Sushi

• Stone-Grilled Seafood Hotpot

• Paiwan Tribe’s Pork Millet Dumplings

• Amis Rice Malt Wine (Herb Koji)

• Seaweed Salad with Koregusu and Lime

These dishes will showcase rare fermentation ingredients brought back from Taiwan, along with easy-to-find alternatives for home cooking.

Saturday, 25 November 2023

Free offer for a new online course on udemy "Course 1: The Essence of Japanese Fermentation"

Welcome to "Course 1: The Essence of Japanese Fermentation"

Discover the Art of Japanese Fermentation

Join Chisato Maeda, a fermenter and ethno-botanist, on a culinary journey through Japan's rich fermentation heritage. Our course, "The Essence of Japanese Fermentation: Comprehensive Guide from Ancient Traditions to Home Cooking," offers a deep dive into the world of Koji, miso, soy sauce, and much more.

Unlock the Secrets of Traditional Japanese Fermentation in Your Own Kitchen!

Free coupon in 31 days

Here are free coupon offering for you, upon launching the new course.

Limited Time Offer: Get 100 Exclusive Udemy Redemptions with Code 7CDF46D90E2A986392AF (Expires in 31 Days)

https://www.udemy.com/course/the-essence-of-japanese-fermentation/?couponCode=7CDF46D90E2A986392AF

.jpg) |

Why This Course?

- Cultural Insight: Explore the historical and traditional aspects of Japanese food culture.

- Scientific Exploration: Gain a thorough understanding of the chemistry and biology behind fermentation processes.

- Hands-On Learning: Engage in practical home experiments to bring your knowledge to life.

- Foundation for Specialization: Ideal for culinary enthusiasts, professionals, and anyone passionate about wellness and Japanese cuisine.

Course Structure

- Module 0: Preparation for Your Fermentation Journey

- Module 1: The Culinary Canvas of Japan: Food Culture and Fermentation

- Module 2: Basics of Fermentation Science

- Module 3: Introduction to Japanese Fermented Products

- Module 4: Crafting “Ichiju Sansai (one soup, three dishes)” with Practical Recipes

What you will gain from this course

Benefit 1: Comprehensive Textbook

You will receive a 100-page PDF textbook filled with in-depth knowledge, tips and secrets about Japanese fermentation at the end of the course.

Benefit 2: Seasonal one-soup-three-course recipes

You will receive 10 seasonal one-soup-three-course recipes (5 for spring/summer and 5 for fall/winter).

Assignment 1: Miso Tasting Challenge

Develop your sense of taste through miso tasting. Understand the characteristics of various types of miso and practice incorporating them into your daily diet.

Assignment 2: Making pickling beds

Students will practice making pickling beds and pickle familiar foods. Pickle beds such as miso pickles, yogurt miso, traditional 358 pickles, and amasu-zuke pickles.

Assignment3: Crafting Ichiju Sansai

Apply your knowledge from the course to design a seasonal "Ichiju Sansai" menu that captures the essence of the selected season through a harmonious blend of flavors, textures, and nutrition.

Q&A

Q: What are some of the key ingredients used in the cooking lessons for this course?

A: Key ingredients include various types of fermented seasonings miso, soy sauce, vinegar, sake and mirin. Also Japanese foods such as tofu, seaweed, radish, konjac, etc.

Q: What should I do, if these ingredients are not available in my county?

A: Alternative ingredients are suggested instead of using specific ingredients which are unique to Japan.

Q: What is "Ichiju Sansai," and how is it relevant to the course content?

A: "Ichiju Sansai" refers to the traditional Japanese meal structure of one soup and three side dishes. The course teaches how to create meals using this structure, highlighting the use of fermented seasonings.

---------------

Please find the detail in the link below:

udemy course "Course 1: The Essence of Japanese Fermentation"

Wednesday, 12 August 2020

Natural dye and cooking from Kihada (Amur cork) tree

Natural dye

The bark can be used for natural dye.Cooking

Saturday, 27 June 2020

Natural plant dye with traditional cooking pot

Today, I learned how to dye with Ruri-san, who taught me how to dye in Southeast Asia.

Ruri Kitadai's blog "Travel and Colors" (Japanese only)

http://rurilapis.blogspot.com/

Collecting plants while listening to stories about how to make mordant liquid and the wisdom of textiles and plants from Asian countries.

まずは羽窯で染液づくり。よもぎをぐつぐつ煮出していきます。

鉄媒染は、酢と鉄釘を混ぜたものでオリーブ色に。ミョウバン媒染は黄色になります。

Strain the mugwort through a colander and place the cloth in the dye solution; simmer for 20 minutes. As soon as it boils, the water overflows, so it is difficult to maintain the heat at low heat. I need to change the charcoal material at the beginning, middle and end of the cooking as same as the Okudosan cooking. The same as stewing, you have to turn off the heat and let it soak until it cools down so that it will gradually soak through.

(Silk can be dyed as it is because of its animal protein, but hemp and cotton have been pre-treated with Kureju (Japanese soup). There are many different ways to prepare the groundwork for dyeing in different countries, so it is interesting to think about dyeing folklore. (It's interesting to think about dyeing folklore because there are many different ways to prepare the groundwork in different countries.

Translated with www.DeepL.com/Translator (free version)

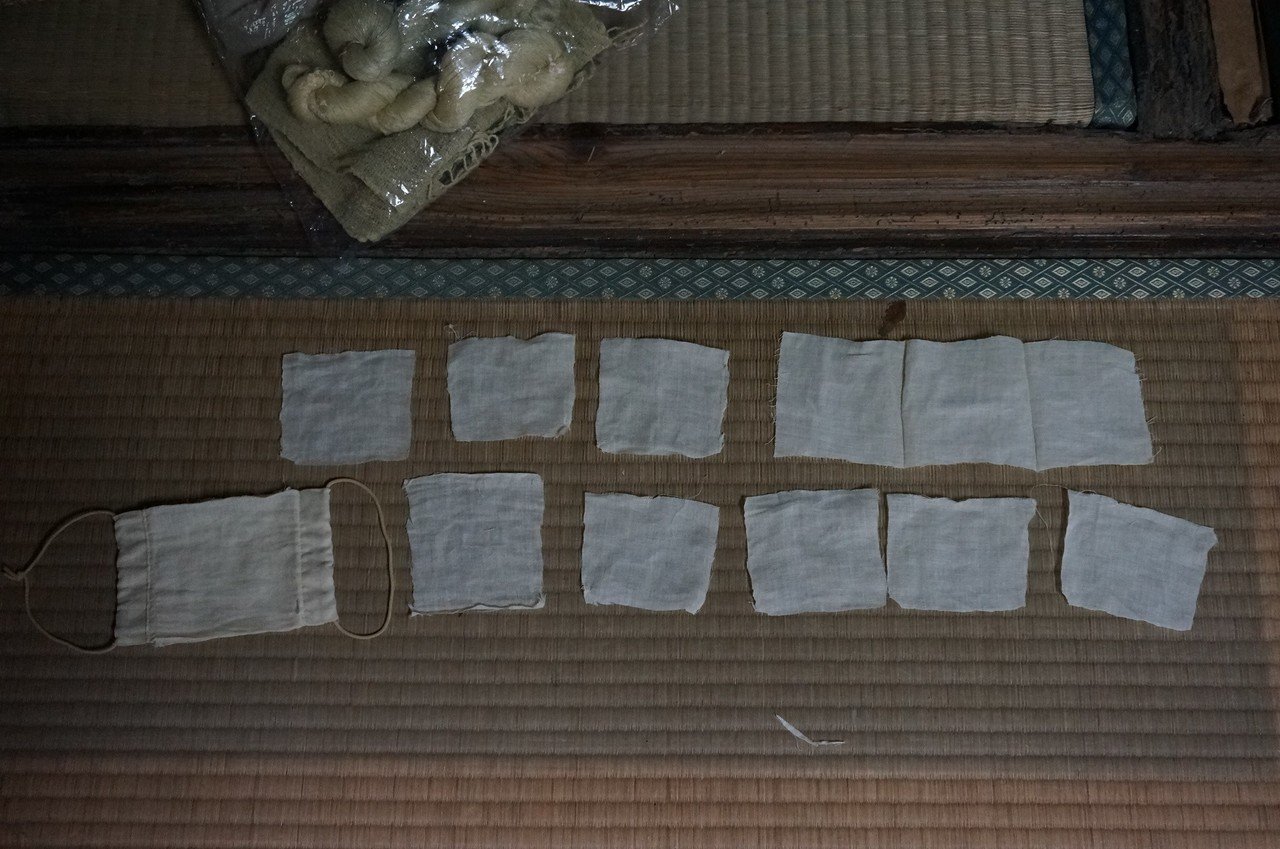

Abeno-mask looks nice when it is dyed

Abenomask is disassembled

I made galette with buckwheat flour for lunch. This is difficult. If it's not spread thin, it's just a crepe. Topped with sesame seeds from the garden, arugula, parsley and sprinkles.

同じ染料でも、媒染液や布の材質によって様々な色に染め上がりました。

Making kakishibu persimmon juice for natural dye

Yamanobe no michi and kaki persimmon cultivation

Yamanobe ancient trail runs along the eastern edge of the Nara Basin. Persimmon fields are dotted around the trail with full of ancient tombs with keyhole-shaped mounds.Actually, Nara Prefecture is the second largest production site of persimmons (kaki) in Japan, and along the Yamanobe trail, the Tonegaki and Hiratane species are well grown. However, did you know that more than 80% of the persimmons are thrown away?

Only one persimmon per branch can be harvested, and the remaining 3/4 of the fruit is thinned-out. This process takes one hour per tree. Persimmon farmers are aging, and they tend to give up producing kaki due to the lack of labor and the high shipping prices of persimmons despite of low income. They are not able to hold back.

We help thinning kaki, and received green persimmons in return, and make persimmon juice, kakishibu.

One is for freshly squeezed persimmon tannin and the other is for aged persimmon tannin.

Raw squeezed persimmon tannin is cooked in a cauldron and the dyeing color is extracted.

In case of freshly pressed persimmon juice, the color turned creamy.

How does the color change when it will be fermented?

We need to keep stiring for 10 days, then, filtered. The liquid will be fermented and aged for at least 1 year. Longer is better.

This juice is made in 3 years ago. It got dark brown.

Tuesday, 18 February 2020

Visit small-scale fermented food manufacturers in Mikawa Aichi prefecture

Fermentation in Mikawa, Aichi prefecture

Aichi is now famous for a major producer of cars, Toyota company, and also steels, but actually, it is also cluster area of food producers. Mikawa, Aichi prefecture is one of the best places to produce koji rice mold. There are many breweries of fermented seasonings such as soy sauce, miso, vinegar sake and mirin. Indeed, Mikawa can be said to be a fermentation district.The reasons why there are so many fermented food manufacturers in Mikawa are:

- good climate

- blessed with nature (mountain, water sources and ocean)

- development of shipping industry in Edo period 17th century

- 5th biggest sake production site

Traditionally, sake was transported and sold in Edo (current Tokyo). Sake residues are recycled to make kasu-zuke (sake lee pickle), vinegar, and amazake (milky sweet sake).

It was really suitable for shipping companies to transport food products from Mikawa to Edo and to Osaka, since it is conveniently located in the middle of Japan in-between Edo(east) and Osaka(west), and compared to Osaka port, the tide flow is stable in Mikawa.

|

| Mizkan vinegar factory along the canal |

Hacho miso

Hatchō Miso has been made in Okazaki area for a long time since 1645. It's made from just soy bean and salt without using rice or wheat mold, which is very unique to Aichi Prefecture.

Steamed soybeans are mixed with bean koji (fermented soy) and formed into miso balls. The miso ball koji are mixed with salted water and put into a big wooden barrel to be fermented for 2 years.

The unique point of Hacho miso is to use around 500 river stones with a weight of 3 tons are put on top in conical shaped mounds, after sealing the miso ball into the wooden barrels.

There are two company in Okazaki to produce Hacho miso until now, and there is factory tours to learn about this unique miso ball fermentation culture in Aichi.

You can taste Hacho miso in the restaurant. The flavor is very thick and dense, and it goes well with tonkatsu miso and also oden.

Mikawa mirin

The history dates back to 600 years ago. Mirin became popular among especially women, since mirin is sweeter and with less alcohol than sake. It's used for teriyaki sauce (sweet sauce for stewed chicken, yakitori), for boiled fish, and sometimes small amount of mirin can be also used instead of sugar.

I have visited Sumiya Bunjo Shoten and Sugiura Mirin. Both are family-run small-scale mirin producers, which produce

Sumiya Bunjo Shoten

Sugiura Mirin

vinegar

Japanese vinegar, called "su" is made from rice. Can you imagine how rice will be vinegar? In Mikawa, there is a great vinegar museum, where you can learn the activities of microbes, which convert sugar into alcohol, and alcohol into vinegar.Mitsukan, a large scale vinegar manufacturer was once a sake brewery.

Miyamoto koji mold producer

Koji (fermentation starters, comprising aspergillus or other microorganisms cultured on the surface of soybeans, rice, or barley grains) plays an essential role in the fermentation process.

Miyamoto koji ten produces multiple types of koji all year around (rice koji, mugi wheat koji, bean koji). It also produces miso during winter season from December to March.

Fermentation learning

Aichi is the perfect place to learn about fermentation culture and Japanese seasonings. There are many family-run traditional producers of miso, tamari shoyu, mirin, sake and vinegar, which keep their traditional way of brewing.Please visit Aichi and learn Japanese knowledge of fermentation.

.jpg)